COMBITHERM

Thermal covers

Thermal covers - safe transport and storage of

temperature-sensitive goods

Particularly within the food and pharmaceutical industry, compliance with specific temperature requirements is essential in connection with both transport and storage, to maintain the cold chain and for the goods to arrive in optimal condition.

Combitherm thermal covers are an effective solution when the goods must be protected against temperature excursions or contamination from the environment without any use of electricity or other energy.

Noticeable advantages

- Insulation made of 78% rPET fibres

- Safe and simple maintenance of the cold chain

- Effective protection against ambient temperature excursions

- Temperature stabilisation from a few hours to several days

- Hygienic and easy to clean

- Light, flexible and easy to handle

- Option for food-approved foils

- High reflection of cold, heat and sunlight optimises temperature stabilisation

IBC thermal covers

Combitherms IBC thermal covers are designed to protect temperature-sensitive liquids during transport and storage in IBC tanks. The covers provide double protection by insulating against both cold and heat. Additionally, the IBC thermal covers protect the tank's contents from sunlight.

The IBC thermal covers are used in the pharmaceutical, food, and chemical industries to safeguard pharmaceutical solutions, active ingredients, food products, chemicals, oil, paint, and other temperature-sensitive products where maintaining a stable temperature is crucial for quality.

Combitherms IBC thermal covers are available in standard sizes for 600, 1000, and 1250-liter tanks.

Quality, Inside Out

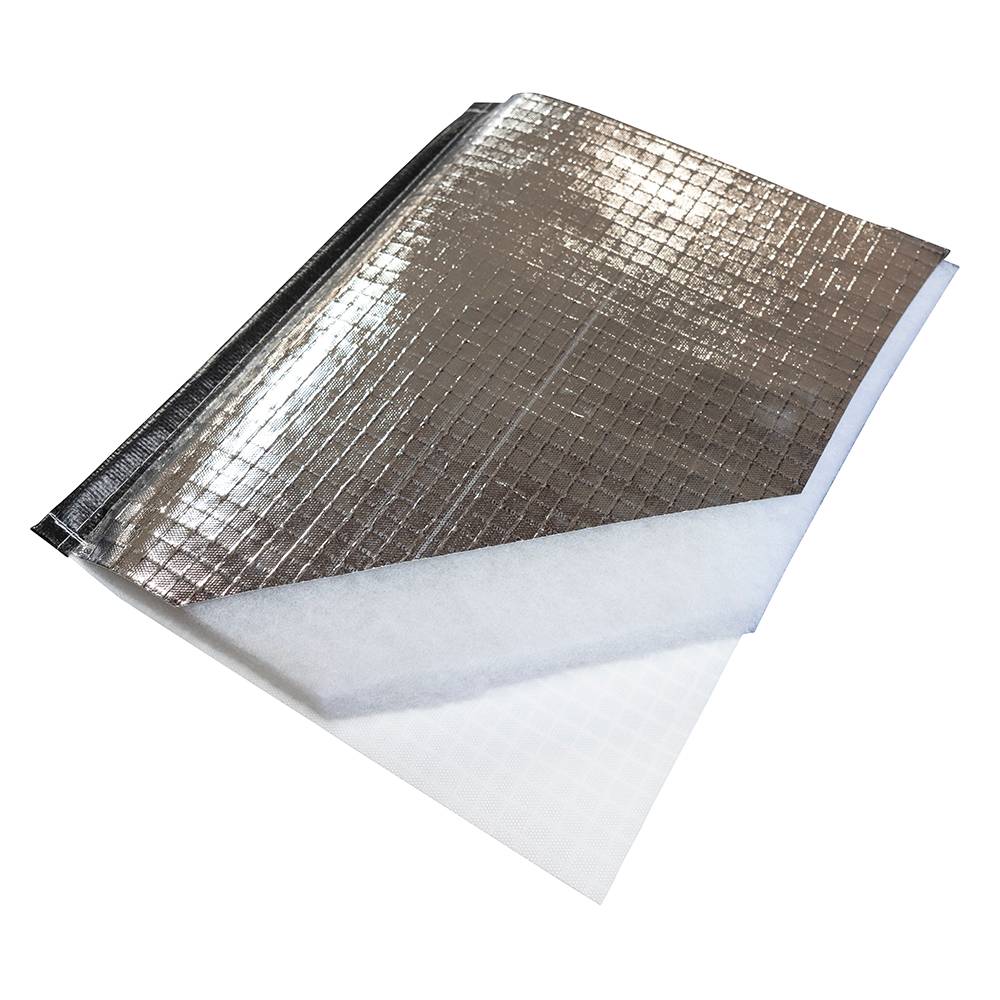

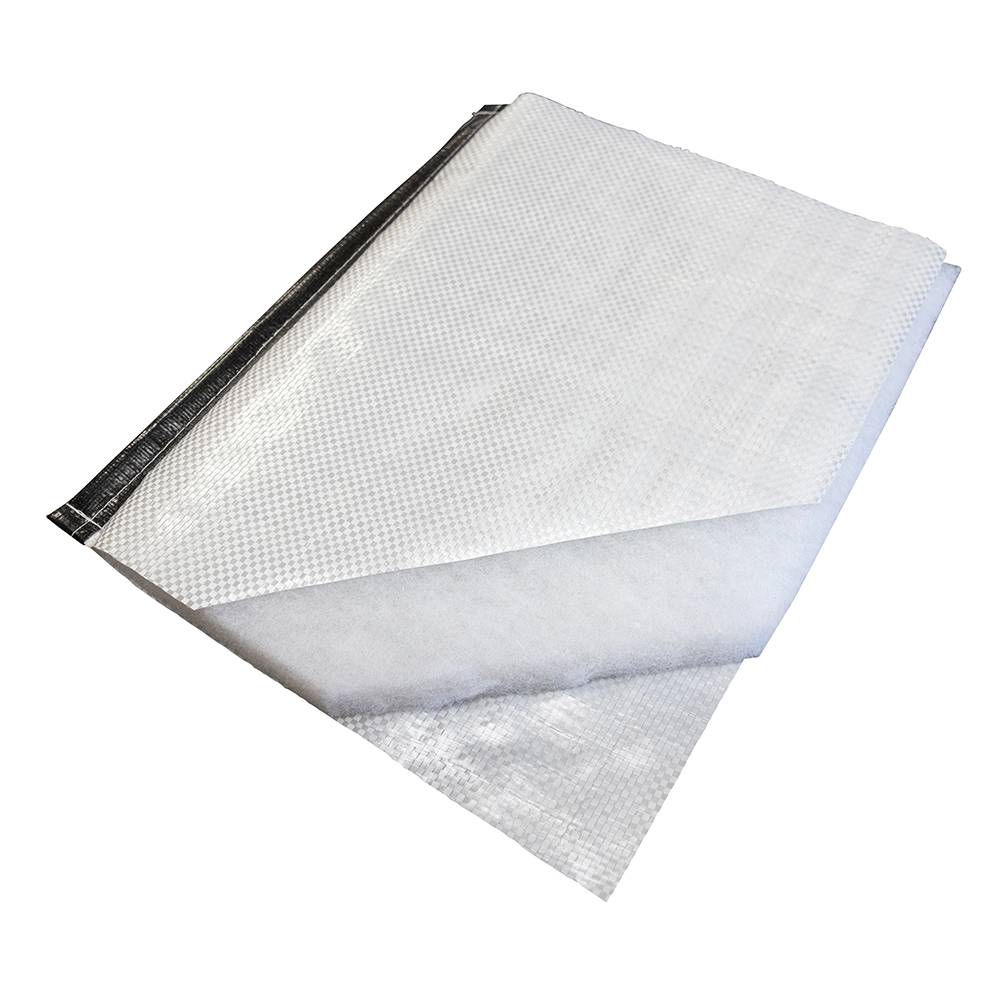

Combitherm thermal covers have been developed with a focus on quality and durability. The thermal solution is based on a strong multi-layer construction with efficient Polywool insulation with spiral polyester hollow fibres and a selection of foils for temperature stabilisation of, for example, food, medicine, chemicals, cosmetics and paint, and for transport by lorry, plane and ship.

Customised thermal solutions

Individual design and high flexibility ensure easy protection of temperature-sensitive goods and provide extra insulation value.

Combitherm thermal cover solutions also include barrel covers, roll cage covers, pallet covers and air cargo covers.

All types of thermal covers may be manufactured in a wide variety of sizes, foil types and insulation thicknesses depending on customer-specific requirements and needs.

Caring about the environment

An uncompromising choice of materials and a proven design mean that Combitherm thermal covers have a long lifespan and can be reused time and time again.

Polywool insulation consisting of 78% recycled fibres helps to increase sustainability and overall the effective insulating ability means that the thermal covers are an economically sound alternative to active cooling units.

Materials

MET

Black edging

PE100

Black edging

PE140

Black edging

PP

Black edging

TEX-PUR

PUR edging

Case: DHL

Air cargo covers is an optimal solution for DHL

DHL specialises in global transport solutions in all emerging markets, including the food and pharmaceutical industries, where the requirements for correct temperature are in focus throughout transport. The solution from Combitherm was and is “rather simple” according to Hanne Reher: A specially sewn cover that can cover an air-cargo pallet with eight Euro-pallets, while at the same time maintain the desired temperature.

Industries

Transportation

Pharmaceuticals

Food

Chemistry

Find the nearest distributor

Please select a country below and see the nearest distributor of thermal covers.